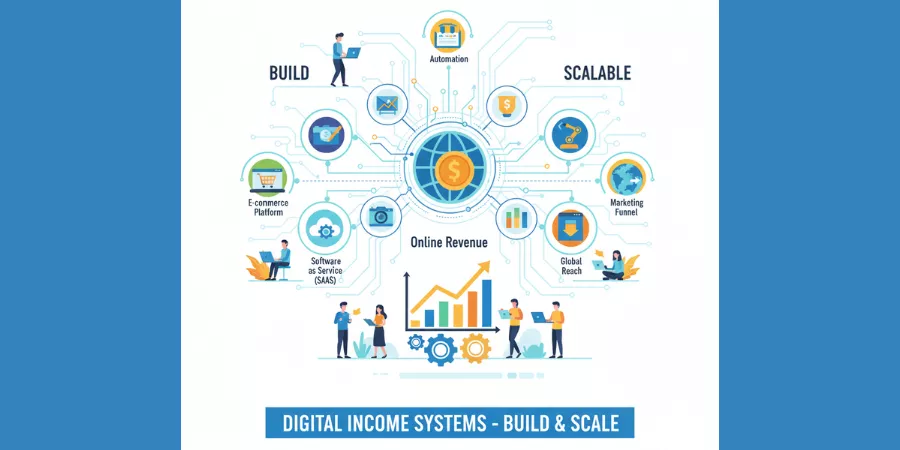

Technological transformation across industries creates substantial workforce development challenges as automation, digitalization, and advanced systems fundamentally alter job requirements, skill demands, and career pathways that defined occupations for decades. The transportation sector exemplifies these dynamics where understanding ADAS (Advanced Driver Assistance Systems), electric vehicle technologies, data analytics, and connected vehicle platforms increasingly distinguish employable workers from those facing obsolescence despite years of experience in traditional roles. Understanding workforce adaptation to technological change requires examining how specific technologies transform occupational requirements, analyzing training and education systems’ capacity to develop new competencies at scale, evaluating labor market dynamics as workers transition between declining and emerging roles, assessing policy frameworks supporting workforce transitions, and recognizing both opportunities and challenges technology creates for workers, employers, and communities dependent on evolving industries. This comprehensive analysis explores workforce development through multiple lenses skills evolution, training delivery, economic implications, and strategic responses providing frameworks for understanding and navigating technological labor market disruption affecting millions of workers globally.

Technological Change and Skills Obsolescence

Technological advancement creates ongoing tension between existing workforce competencies and emerging job requirements.

The Nature of Technological Disruption in Labor Markets

Technology affects employment through multiple mechanisms operating simultaneously:

Task Automation:

Technology performing tasks previously requiring human labor:

- Routine Cognitive Tasks: Software automating data entry, basic analysis, scheduling, and administrative functions

- Routine Manual Tasks: Robotics and automation replacing assembly line work, warehouse operations, and repetitive physical tasks

- Non-Routine Tasks: AI and machine learning increasingly handling complex pattern recognition, decision-making, and creative tasks previously thought automation-resistant

Skill-Biased Technological Change:

Technology disproportionately benefiting high-skilled workers while displacing middle-skill occupations:

| Skill Level | Technology Impact | Employment Trend | Wage Trend |

|---|---|---|---|

| High-Skill (Professional, Technical) | Complementary technology enhances productivity | Growing | Rising |

| Middle-Skill (Routine Cognitive/Manual) | Substitutive technology replaces tasks | Declining | Stagnant/Declining |

| Low-Skill (Non-Routine Manual Service) | Mixed some automation, geographic constraints | Stable/Growing | Flat |

Job Polarization:

Labor market exhibiting growth at high and low ends while middle-skill jobs decline:

- High-skill professional and technical occupations expanding

- Middle-skill routine occupations contracting through automation

- Low-skill service occupations growing (healthcare aides, food service, personal care)

- “Hollowing out” of middle-skill jobs historically providing middle-class incomes

Transportation Industry Case Study: Technological Transformation

The transportation and logistics sector demonstrates how technology reshapes occupational requirements across skill levels:

Traditional Truck Driver Role:

Historical requirements emphasized:

- Commercial driver’s license (CDL) training and testing

- Vehicle operation and maneuvering skills

- Route navigation and time management

- Basic vehicle maintenance knowledge

- Hours of service compliance

Evolving Requirements Adding Complexity:

Modern commercial drivers increasingly need:

- ADAS System Understanding: Operating vehicles with lane departure warnings, adaptive cruise control, collision avoidance systems requiring driver adaptation

- Telematics Literacy: Working with systems monitoring driving behavior, fuel consumption, and location telematics monitors driving habits requiring drivers to understand performance metrics and optimization

- Electronic Logging Devices (ELD): Compliance with digital hours-of-service recording

- Route Optimization Software: Using GPS and traffic systems for efficient routing

- Customer Service Technology: Managing delivery confirmations, electronic signatures, mobile communications

Fleet Management Transformation:

Fleet managers evolved from:

- Vehicle acquisition and disposal

- Driver hiring and scheduling

- Basic cost tracking

To requiring:

- Data Analytics: Interpreting vehicle performance data, fuel consumption patterns, maintenance predictions

- Telematics Platform Management: Optimizing routes, monitoring driver performance, ensuring regulatory compliance through data

- Technology Integration: Managing software platforms for dispatch, tracking, maintenance scheduling

- Electric Vehicle Fleet Planning: As electric vehicles are becoming increasingly prevalent, planning charging infrastructure, understanding EV economics

Maintenance Technician Evolution:

Traditional diesel mechanic skills:

- Engine diagnostics and repair

- Brake systems and suspension

- Hydraulic and pneumatic systems

- Electrical systems (12-24 volt)

Expanding to include:

- High-Voltage Systems: Working with EV battery systems (400-800 volt)

- Electronic Control Systems: Diagnosing computer-controlled systems and sensors

- ADAS Calibration: Aligning and calibrating advanced sensor systems

- Software Diagnostics: Understanding vehicle software and updates

- Hybrid Powertrains: Combining traditional and electric propulsion knowledge

Training and Education System Response

Workforce development institutions face substantial challenges adapting to rapidly changing skill requirements.

Traditional Education Model Limitations

Conventional education and training systems struggle with technological change pace:

Long Development Cycles:

- Curriculum development requires years from identification to implementation

- Accreditation processes ensure quality but slow adaptation

- Textbook and material development lag current technology

- By program completion, technology may have evolved substantially

Institutional Inertia:

- Educational institutions resistant to rapid change

- Faculty expertise concentrated in established subjects

- Capital investments in equipment and facilities create path dependence

- Administrative structures designed for stability, not agility

Disconnection from Industry:

- Academic programs prioritize theoretical foundations over current tools

- Limited industry partnerships informing curriculum

- Equipment in training facilities often older than current industry standards

- Faculty lack recent industry experience

Emerging Training Models and Delivery Mechanisms

Innovation in training delivery addresses some traditional limitations:

Competency-Based Education:

Focus on demonstrable skills rather than seat time:

- Students advance upon proving competency regardless of time required

- Allows self-paced learning accommodating working adults

- Assessment focused on practical application

- Faster pathways for quick learners, additional support for those needing more time

Micro-Credentials and Stackable Certificates:

Modular credentials targeting specific skills:

- Short-duration programs (weeks to months) versus degree programs (years)

- Industry-recognized credentials demonstrating specific competencies

- Stackable toward larger credentials or degrees over time

- Enables incremental skill development while employed

Online and Hybrid Learning:

Technology-enabled training delivery:

- Online theory components with in-person practical training

- Asynchronous learning accommodating work schedules

- Simulation and virtual reality for skill practice

- Geographic barriers reduced for theory components

Industry-Integrated Programs:

Closer alignment between training and employment:

- Apprenticeships combining classroom and work-based learning

- Employer involvement in curriculum design

- Equipment donations keeping training current with industry standards

- Guaranteed employment pathways for completers

Example Commercial Driver Training:

Modern truck driver training in Somers and similar programs increasingly integrate:

- Traditional CDL skills (vehicle operation, maneuvering)

- Technology systems (ELD compliance, telematics, route optimization)

- Safety systems (ADAS features and operation)

- Customer service and professional conduct

- Both Class A (tractor-trailer) and Class B (straight truck) endorsements

This integration ensures graduates enter workforce with contemporary skill sets rather than legacy competencies requiring employer retraining.

Labor Market Dynamics and Worker Transitions

Technological change creates complex labor market adjustments as workers navigate transitions between declining and emerging roles.

Skills Transferability and Career Pathways

Worker transitions depend on transferability of existing skills to new roles:

Skill Categories and Transferability:

| Skill Type | Examples | Transferability | Implications |

|---|---|---|---|

| Job-Specific Technical | Specific equipment operation, proprietary systems | Low | Requires retraining for role changes |

| Industry-Specific Knowledge | Regulatory frameworks, industry standards | Moderate | Transfers within industry, not across |

| General Technical | Computer literacy, data analysis, problem-solving | High | Valuable across roles and industries |

| Social/Cognitive | Communication, teamwork, critical thinking | High | Foundation for diverse occupations |

Transition Challenges:

Workers with primarily job-specific technical skills face greatest transition difficulty:

- Years of experience become less valuable as technology changes

- Compensation often tied to seniority, discouraging lateral moves

- Identity and self-worth connected to occupational expertise

- Geographic constraints limiting mobility to areas with opportunities

Successful Transition Factors:

- Strong foundational skills (literacy, numeracy, digital literacy)

- Learning agility and openness to change

- Access to training opportunities

- Financial resources supporting transition period

- Geographic mobility enabling relocation to opportunity areas

Age and Experience Effects

Worker age significantly affects technological adaptation and transition success:

Younger Workers:

Advantages:

- Digital natives comfortable with technology

- Longer career horizon justifying training investment

- Greater career flexibility and mobility

- Less experience with legacy systems to “unlearn”

Challenges:

- Less industry knowledge and professional networks

- Limited financial resources for training

- Competing family and financial obligations

Mid-Career Workers (35-55):

Advantages:

- Established industry knowledge and networks

- Peak earning years providing financial resources

- Professional maturity and work ethic

Challenges:

- Family and mortgage obligations reducing risk tolerance

- Established career identities resistant to change

- Training investment has fewer years to recoup

- May face age discrimination in hiring for new roles

Older Workers (55+):

Advantages:

- Extensive industry knowledge and experience

- Financial stability (in many cases)

- Strong work ethic and reliability

Challenges:

- Training ROI questioned with limited remaining career years

- Age discrimination in hiring and training access

- Physical demands of some occupations increasing with age

- Less familiarity with digital technologies in many cases

Gender and Demographic Dimensions

Technological change affects demographic groups differently:

Occupational Segregation:

- Men overrepresented in manufacturing and trades facing automation

- Women overrepresented in administrative and clerical roles automating

- Both genders concentrated in occupations with significant technological disruption

Training Access Disparities:

- Women face caregiving responsibilities limiting training participation

- Minority workers underrepresented in apprenticeship and technical training

- Rural workers face geographic barriers to training facilities

- Lower-income workers lack financial resources for training costs

Pathway Diversification:

Increasing recognition that diversifying workforce in emerging technical fields requires:

- Active recruitment in underrepresented populations

- Addressing structural barriers (childcare, transportation, financial aid)

- Mentorship and support networks

- Organizational culture change in male-dominated fields

Economic Implications for Workers and Communities

Technological workforce transitions create significant economic effects at individual, organizational, and community levels.

Individual Economic Impacts

Workers navigating technological transitions face various economic outcomes:

Successful Adaptation:

Workers successfully upskilling may experience:

- Wage increases from more valuable skills

- Greater job security in growing occupations

- Career advancement opportunities

- Professional satisfaction from skill development

Displacement and Downward Mobility:

Workers unable to adapt face:

- Job loss and unemployment periods

- Wage reductions accepting lower-skill positions

- Benefit losses (health insurance, retirement)

- Long-term earnings impacts reducing lifetime wealth accumulation

- Psychological impacts (stress, depression, loss of identity)

Training Investment Economics:

Worker cost-benefit calculations for training:

Costs:

- Tuition and fees

- Foregone earnings during training

- Childcare and transportation

- Books and equipment

- Opportunity costs of time

Benefits:

- Higher wages in new occupation

- Greater job security and advancement

- Career satisfaction

- Lifetime earning potential

Break-even Analysis:

Training justifies cost if lifetime earnings increase exceeds total investment costs. Older workers have shorter periods to recoup investments, making training economically questionable absent other benefits.

Employer Perspectives and Incentives

Employers face their own calculations regarding workforce development:

Make-or-Buy Decision:

Employers choose between:

Invest in Existing Workforce (“Make”):

Advantages:

- Retain institutional knowledge and culture

- Build employee loyalty and reduce turnover

- Customize training to specific organizational needs

Costs:

- Training program development and delivery costs

- Productivity loss during training

- Risk of trained workers leaving for competitors

Hire Trained Workers (“Buy”):

Advantages:

- Immediate access to required skills

- No training investment or productivity loss

- Flexibility to scale workforce up or down

Disadvantages:

- Higher wages commanding necessary skills

- Reduced employee loyalty and higher turnover

- Culture fit and integration challenges

- May not find workers with exact skill combinations needed

Poaching Problem:

Collective action problem in employer training investment:

- Individual employers underinvest in training fearing worker poaching

- Creates systemwide shortage of trained workers

- Industry associations and government may need to coordinate training

- Apprenticeship systems and training standards address this through shared investment

Community and Regional Impacts

Technological transitions affect entire communities, particularly those concentrated in disrupted industries:

Manufacturing-Dependent Communities:

Former manufacturing centers face:

- Job losses from automation and offshoring

- Population decline as workers leave for opportunities

- Tax base erosion affecting public services

- Downtown deterioration as business activity declines

- Social challenges (substance abuse, family dissolution)

Successful Transition Examples:

Some communities successfully transitioned:

- Pittsburgh: From steel manufacturing to healthcare and technology

- Chattanooga: From textile manufacturing to advanced manufacturing and tech

- Grand Rapids: From furniture manufacturing to diverse economy

Success Factors:

- Anchor institutions (universities, hospitals) providing stability

- Infrastructure investment (broadband, transportation)

- Business attraction and entrepreneur support

- Workforce training aligned with emerging industries

- Community leadership and collaborative planning

Unsuccessful Transitions:

Many communities struggle with:

- Limited resources for transition investments

- Geography or infrastructure disadvantages

- Population already out-migrated

- Legacy environmental contamination

- Aging population with limited adaptability

Policy Frameworks Supporting Workforce Transitions

Government policies at multiple levels can facilitate workforce adaptation to technological change.

Publicly-Funded Training Programs

Government invests in workforce development through various mechanisms:

Workforce Innovation and Opportunity Act (WIOA):

Primary U.S. federal workforce development program:

- Formula grants to states for training and employment services

- Career centers providing job search, counseling, and training referrals

- Support for displaced workers through dislocated worker programs

- Youth programs for skills development

Community College Funding:

Federal and state support for community colleges:

- Affordable tuition enabling access

- Technical programs aligned with regional labor needs

- Partnerships with employers and industry

- Remedial education addressing skill gaps

Trade Adjustment Assistance (TAA):

Support for workers displaced by international trade:

- Extended unemployment benefits

- Training funding beyond standard programs

- Job search and relocation allowances

- Wage insurance for older workers accepting lower-paying jobs

Program Effectiveness:

Evaluation research shows mixed results:

- Positive impacts often modest (5-10% earnings increases)

- Variation across programs and participant characteristics

- Long-term benefits may exceed short-term impacts

- Quality of training and labor market conditions affect outcomes

Educational Access and Affordability

Reducing barriers to training participation:

Tuition Subsidies:

- Pell Grants for low-income students

- State tuition assistance programs

- Employer tuition reimbursement benefits

- GI Bill benefits for veterans

Loan Forgiveness and Income-Driven Repayment:

- Public Service Loan Forgiveness for public sector employment

- Income-driven repayment capping payments as percentage of income

- Loan forgiveness after specified payment period

- Reduces risk of training investment not paying off

Support Services:

- Childcare assistance enabling parent participation

- Transportation vouchers or assistance

- Emergency financial assistance for unexpected costs

- Advising and counseling supporting student success

Tax Incentives for Employer Training

Encouraging employer investment in workforce development:

Training Tax Credits:

- Credits for employee training expenses

- Apprenticeship tax credits

- Equipment donations to training institutions

Effectiveness Questions:

- May subsidize training employers would do anyway

- Administrative complexity limiting participation

- Difficult targeting to priorities versus general subsidies

Labor Market Information Systems

Supporting informed career and training decisions:

Occupational Projections:

- Employment growth forecasts by occupation and region

- Wage data for career comparison

- Educational requirements and pathways

- Skills and knowledge needed

Real-Time Labor Market Data:

- Job posting analytics showing current demand

- Skills requirements from employer listings

- Wage offers in current market

- Geographic variation in opportunities

Training Program Outcomes:

- Completion rates by program

- Graduate employment and earnings

- Student debt levels

- Return on investment calculations

Information Access:

Making data accessible to workers, students, and counselors:

- User-friendly websites and tools

- Integration with career counseling

- Outreach to underserved populations

- Regular updates reflecting changing markets

Strategic Responses for Workers, Employers, and Institutions

Stakeholders at all levels can implement strategies facilitating successful technological transitions.

Individual Worker Strategies

Workers can proactively manage career development:

Continuous Learning Orientation:

- Viewing learning as career-long process, not one-time education

- Staying current with industry trends and technologies

- Seeking professional development opportunities

- Learning agility as core competency

Skill Portfolio Diversification:

- Developing transferable skills valuable across roles

- Combining technical and social skills

- Industry knowledge plus adjacent capabilities

- Avoiding over-specialization in narrow technical skills

Career Monitoring and Planning:

- Tracking industry trends and automation threats

- Identifying emerging opportunities and requirements

- Planning training investments strategically

- Building professional networks and relationships

Financial Preparation:

- Emergency funds supporting transition periods

- Manageable debt levels enabling flexibility

- Understanding training costs and ROI

- Utilizing available financial assistance

Employer Best Practices

Progressive employers implement comprehensive workforce development strategies:

Skills-Based Hiring:

- Focusing on competencies rather than credentials

- Apprenticeships and on-the-job training pathways

- Internal promotion and skill development

- Reducing unnecessary degree requirements

Structured Training Programs:

- Formal technical training for new technologies

- Tuition assistance for external education

- Internal career pathways with skill requirements

- Mentoring and knowledge transfer systems

Labor-Management Collaboration:

- Union partnerships on training and transitions

- Employee input in technology implementation

- Advance notice of changes enabling preparation

- Severance and transition support for displaced workers

Talent Pipeline Development:

- Community college and training institution partnerships

- Equipment donations and curriculum input

- Internships and apprenticeships

- Early career recruitment and development

Educational Institution Innovation

Training providers must adapt to support workforce transitions:

Flexible Delivery Models:

- Evening and weekend programs for working adults

- Online and hybrid formats reducing geographic barriers

- Accelerated and self-paced options

- Modular credentials enabling incremental progress

Industry Engagement:

- Advisory boards guiding curriculum development

- Employer partnerships for equipment and expertise

- Work-based learning integration

- Job placement services and employer connections

Rapid Curriculum Updates:

- Regular review cycles keeping pace with technology

- Industry-validated competency frameworks

- Faculty professional development in current practices

- Equipment refresh schedules maintaining relevance

Support Services:

- Financial aid and emergency assistance

- Childcare and transportation support

- Academic advising and career counseling

- Tutoring and academic support services

Technological Optimism Versus Dystopian Concerns

Debates about technological change in labor markets reflect fundamentally different assumptions and values.

Optimistic Perspectives

Technology proponents emphasize positive possibilities:

Historical Pattern of Adaptation:

- Previous technological revolutions (industrial, computer) ultimately increased living standards

- Creative destruction creates new occupations replacing old ones

- Productivity growth enables wage increases and reduced working hours

- Humans have always adapted to technological change

Quality of Work Improvements:

- Automation eliminates dangerous, repetitive, physically demanding tasks

- Workers focus on higher-value, cognitive, and interpersonal activities

- Greater workplace flexibility and work-life balance

- Technology augments human capabilities rather than replacing workers

Policy Solutions Available:

- Education and training can prepare workers for new roles

- Social safety net catches those struggling with transitions

- Economic growth from productivity funds transition support

- Past transitions successfully managed, future transitions possible

Dystopian Concerns

Critics emphasize potentially negative trajectories:

This Time Is Different:

- AI and robotics capable of automating cognitive and physical tasks simultaneously

- Speed of change exceeds adaptation capacity

- Education cannot keep pace with automation advancement

- Massive technological unemployment possible

Inequality Exacerbation:

- Technology disproportionately benefits capital owners and highly-educated

- Middle-class jobs disappearing without comparable replacements

- Growing gap between winners and losers

- Social cohesion threatens from extreme inequality

Insufficient Policy Response:

- Political will lacking for necessary support programs

- Training effectiveness limited for significant disruptions

- Social safety net inadequate for mass unemployment

- Corporate power prevents worker-protective policies

Evidence and Uncertainty

Current evidence provides mixed signals:

Unemployment Remains Low:

- Despite automation fears, unemployment rates near historical lows in many developed countries

- Labor force participation concerning but not catastrophic

- Job growth in many sectors despite technology

Wage Stagnation Concerning:

- Despite economic growth, median wages flat for decades

- Labor share of income declining

- Growing inequality concentrating gains at top

- Suggests technology changing distribution, not just levels

Transition Challenges Real:

- Displaced workers face significant earnings losses

- Regional concentrations of disruption creating community crises

- Age and education predict success in transitions

- Training programs show modest effectiveness

Uncertainty Remains:

- AI capabilities developing rapidly with unclear implications

- Policy choices will shape outcomes significantly

- Distribution questions more salient than aggregate employment

- Historical patterns may or may not hold

Conclusion: Navigating Workforce Transitions in Technological Change

Technological transformation fundamentally reshaping occupational requirements, skill demands, and career pathways requires comprehensive responses across multiple stakeholders addressing both economic efficiency and social equity concerns. The transportation industry’s evolution requiring workers to master ADAS systems, electric vehicle technologies, telematics platforms, and data analytics exemplifies broader patterns affecting virtually all sectors as digitalization and automation advance.

Several principles should guide workforce development strategies:

Continuous Learning Imperative: Career-long skill development becomes essential rather than optional. Workers, employers, and institutions must embrace ongoing learning as core element of professional life rather than one-time educational experience.

Training System Modernization: Educational institutions must accelerate adaptation through flexible delivery, industry partnership, rapid curriculum updates, and support services enabling working adult participation.

Multi-Stakeholder Responsibility: Successful transitions require shared commitment workers investing in skill development, employers providing training and advancement opportunities, educational institutions delivering relevant programs, and government supporting access and reducing barriers.

Equity Considerations: Technological transitions disproportionately affect certain workers and communities. Policies should address distributional impacts through targeted support, not just aggregate economic efficiency.

Realistic Expectations: Training is not panacea some workers face genuine displacement despite best efforts. Social safety nets must catch those unable to successfully transition through no fault of their own.

Early Intervention: Waiting until job loss occurs makes transitions harder. Proactive skill development while employed, industry early warning systems, and gradual transitions prove more effective than crisis responses.

Regional Strategies: Community-level impacts require coordinated local responses involving economic development, workforce training, infrastructure investment, and business attraction tailored to specific regional circumstances.

For workers navigating technological change:

- Assess current role’s automation vulnerability realistically

- Develop both technical and transferable skills valuable across contexts

- Maintain learning agility and openness to change

- Build professional networks providing information and opportunities

- Plan financial buffers supporting transition periods

- Seek training while employed rather than waiting for displacement

- Consider geographic mobility if local opportunities limited

For employers managing technological transitions:

- Invest in existing workforce rather than defaulting to external hiring

- Provide advance notice and training for technology changes

- Implement skills-based hiring reducing credential barriers

- Partner with training institutions developing talent pipelines

- Support employee development through tuition assistance and internal training

- Consider social responsibility alongside profit maximization

For policymakers and institutions:

- Expand access to affordable, flexible training programs

- Improve labor market information supporting informed decisions

- Strengthen social safety nets catching displaced workers

- Incentivize employer training investment

- Address barriers (childcare, transportation, financial) limiting participation

- Target resources to vulnerable populations and communities

- Coordinate regional strategies rather than fragmented approaches

Technological change presents both opportunities and challenges for workers, employers, and society. Outcomes depend not on technological determinism but on choices made by individuals, organizations, and governments about how to navigate transitions. Proactive, comprehensive, equitable approaches can facilitate adjustment that harnesses technology’s productivity benefits while supporting workers and communities through inevitable disruptions. Neglect or inadequate responses risk exacerbating inequality, creating regional crises, and generating political backlash against technological progress itself.

The goal is not preventing technological change impossible and undesirable given potential benefits but managing transitions in ways that broadly distribute benefits while supporting those disadvantaged through changes beyond their control. This requires sustained commitment, adequate resources, and recognition that workforce development investments are not costs but rather essential foundations for broadly shared prosperity in technologically dynamic economies.