Modern internal combustion engines rely on precision. One key factor people overlook until they need it is ignition timing. When fuel type, engine design, or performance aims change, timing can make or break smooth operation. That is where the Timing Advance Processor (TAP) makes a practical difference.

This guide explains what it is, how it works, what types exist, where it is used, and how to choose the right one for your vehicle or project.

What is a Timing Advance Processor?

A timing advance processor (TAP) is a dedicated electronic unit that finds its application in internal combustion engines and helps answer what is a timing advance processor for many drivers switching fuels. The main purpose of the device is to modify the ignition timing of the engine through precise TAP timing advance, usually by shifting the spark to an earlier point in time with respect to the original engine settings. The timing advance must be done when the engine burns CNG or LPG, and TAP timing advance helps achieve that safely as these fuels do not have the same behavior as petrol.

In layman’s terms, the timing advance processor communicates the ignition systems to fire earlier so that the combustion occurs at the most suitable point considering the variations in burn characteristics. If the timing is wrong, the engines will experience a decrease in torque, rough running, higher consumption of fuel and even backfiring.

Why Ignition Timing Matters

Ignition timing indicates the precise instant when the spark plug ignites the mixture of air and fuel concerning the position of the piston in the cylinder, which makes ignition timing adjustment critical to engine efficiency. If the timing is said to be advanced, it means that the spark is made to occur earlier (when the piston is still ascending to top dead center), and if it is retarded, it will be made to occur later.

The right timing allows the combustion pressure, which is the result of the mixture of three factors that are power, efficiency, and smoothness, to peak at the very moment when it will produce the most in terms of those three factors.

The transition of an engine from petrol to CNG or LPG causes a change in the combustion speed, which is why CNG timing advance becomes necessary. The latter fuels are usually the slowest to burn, and if the timing is not changed from the factory setting, the peak pressure will occur too late in the cycle, which is why LPG timing advance is required. The timing advance processor takes the responsibility of correcting this mismatch by advancing the ignition at the right time.

How a Timing Advance Processor Works

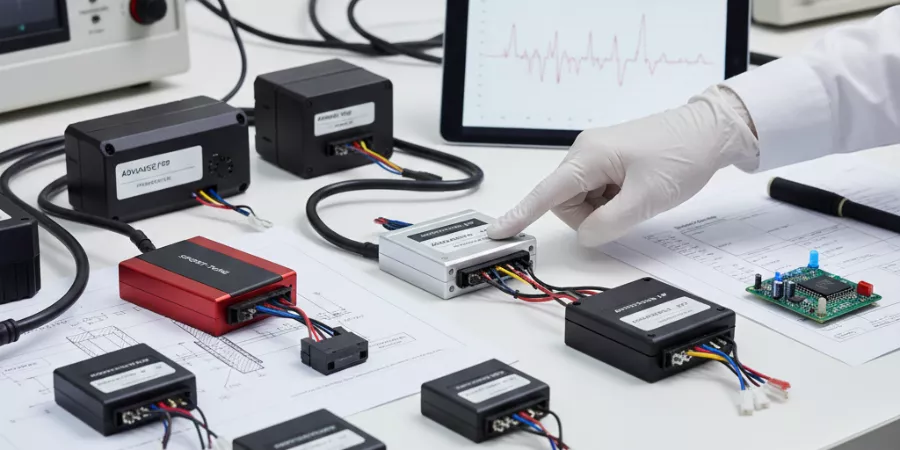

A timing advance processor usually connects to the current ignition system and important components or the ECU, which explains how timing advance processor works in real engine conditions. It checks the signals such as distributor triggers, crankshaft position sensor data, or ignition module outputs.

According to its configuration, it alters the signals so that the spark happens before the stock timing using controlled TAP timing advance.

Most of the time, it does not activate during petrol use and turns on only during the alternate fuel system operation. Some processors use simple switches or trimmers for setting the advance that is to be added, working almost like a timing advance controller in basic form.

The more sophisticated ones use digital logic or coding to dynamically change timing depending on the engine’s speed and load.

Where Timing Advance Processors Are Used

The main application areas of timing advance processors are:

- Vehicles that have been converted from petrol to CNG or LPG and where the gas injection system was initially designed for petrol.

- Engines that have old ignition systems to control the spark timing that use mechanical methods (like breaker points or old electronic ignition).

- High-mileage commercial vehicles such as taxis and delivery fleets where the economy and consistency of fuel are very important.

- Performance tuning applications where the ignition timing can be separated without the need to alter the ECU software often benefit from an aftermarket timing device.

In the case of modern cars with high-tech ECU control, timing can often be changed through remapping, but TAPs are still useful because they allow safer ECU timing modification when direct tuning is impractical or when very simple mechanical systems are still in use, making them an effective aftermarket timing device.

Types of Timing Advance Processors (TAP) Explained

When your petrol engine is converted to run on CNG or LPG, the standard ignition timing no longer matches the slower burn rate of these fuels. Timing advance processors step in to correct that by advancing the spark at the right moment so the combustion finishes where it makes the most power.

The main types used in vehicles today are better grouped by ignition system type, because that determines how the TAP interacts with signals:

- Mechanical Ignition TAPs

- Electronic Ignition TAPs with Distributor

- Electronic Ignition TAPs for Distributorless / Crank Sensor Engines

- Adaptive or Software-Adjustable TAPs

Each type interacts differently with your engine’s sensors and control electronics. Most manuals list specific TAP models for each category, but the principle remains the same: they alter when the spark happens.

1. Mechanical Ignition TAPs

This is the simplest form of timing advance processor. These are used on older engines with coils and distributors with breaker points.

- These cars do not have an ECU controlling spark timing, soTAP timing advance becomes essential, so the TAP has direct control of ignition signal timing.

How It Works

The TAP intercepts the signal from the distributor’s breaker points before it reaches the ignition coil, allowing spark timing control at the source. It then advances the spark by a calibrated amount so the fuel burns more efficiently when the car runs on gas, improving spark timing control.

Typical Installation

- Locate the breaker point lead that goes to the ignition coil.

- Cut that wire and connect the TAP’s input and output accordingly.

- Make solid ground and power connections as specified in the TAP manual.

- Start the engine on gas and measure original timing with a timing gun.

- Rotate the distributor manually so the actual advance is greater than petrol by the recommended value (for example, LPG by ~9° and CNG by ~12° more than the base), creating the proper CNG timing advance.

- Lock the distributor position and verify with the timing light.

Setting these units is done by mechanically adjusting the distributor while the TAP remains in circuit. You are not just plugging in the TAP; you are replacing the advance function your old distributor once gave you.

2. Electronic Ignition TAPs with Distributor

Modern engines with electronic ignition still have a distributor, but they use a pickup sensor and ignition module. TAPs designed for these systems adjust timing before or at the ignition module rather than at breaker points.

How It Works

In these systems, the TAP modifies the signal between the crank/cam sensor and the ignition module or ECU. It either delays, advances, or alters that signal to simulate a different timing advance curve when the engine runs on gas.

Typical Installation

- Identify the correct signal line from crank position or cam position sensor that goes to the ignition module or ECU.

- Tap into that signal with the TAP wiring harness.

- Power, ground and the gas mode activation switch signal should be connected, thus the TAP will be alerted to operate.

- Gas mode start for the engine and measuring the timing with a timing light as your procedure.

- The TAP can be adjusted by trimmer or switches until the measured timing advance and the target values are equal, resulting in accurate ignition timing adjustment.

- Switch back to petrol mode and verify that timing returns to stock values.

These units often have a trimmer or DIP switches to select how much advance is added in gas mode, similar to how a timing advance controller fine-tunes timing. You adjust it so the best compromise of power, smoke, and response is achieved.

3. Electronic Ignition TAPs for Distributorless / Crank Sensor Engines

Newer ICE vehicles do not use a distributor at all. Instead, they rely on multiple coils and crank/cam sensors monitored by the ECU. TAPs in these vehicles must interface with low voltage sensor signals without disturbing the ECU’s logic.

How It Works

These TAPs monitor rotation sensor signals (from crankshaft and sometimes camshaft) and modify them digitally before they reach the ECU. The ECU interprets the modified signal and adjusts timing accordingly as part of controlled ECU timing modification. This technique is often called MAP signal modification or sensor signal emulation.

Typical Installation

- Locate the crankshaft position sensor signal wire(and camshaft if used).

- Install the TAP harness so it can read and alter these signals.

- Provide power and gas mode activation signal so the TAP knows when to change behavior.

- Use the TAP’s configuration interface(often switches or software) to set ignition advance curves for gas mode.

- Use a timing light or diagnostic tool to confirm correct timing under load and idle.

- Set the stock timing curve to return in petrol mode.

This type is more complex to set up because you need exact sensor matching and correct signal levels. Manuals often include sensor type identification steps before installation.

4. Adaptive or Software-Adjustable TAPs

Some advanced timing advance processors allow dynamic adjustment of timing based on engine load, RPM, and other live data. These are often paired with software interfaces.

How It Works

Instead of fixed advance per RPM zone, these TAPs read live signals from:

- crankshaft position

- throttle position

- MAP sensor

- gas activation signal

They then adjust timing in real time to optimize combustion for gas performance across conditions.

Typical Installation

- Connect the TAP wiring to all required sensors(crank, TPS, MAP, gas signal, power, ground).

- Install any required software on a laptop or handheld device to communicate with the TAP.

- Load recommended gas fuel timing profiles into the TAP memory.

- Test on a dynamometer or with live engine data to fine-tune timing maps.

- Adjust live maps to optimize power, emissions, and drivability under real loads.

These units are ideal if you want close-to-ECU level control of ignition advance. They are more complex but deliver the best results when tuned properly.

Installation and Setting for Each Type

Here is a concise but actionable timing advance processor installation guide for each category.

Installation Best Practices (All Types)

Before any installation:

- Make sure the engine is warmed up for timing checks.

- Have a timing light and engine diagnostic tool

- Know whether your vehicle uses breaker points, distributor pickup, crank sensor, or distributorless ignition.

Mechanical Ignition TAP (Breaker Points)

Step-by-Step

- Disconnect battery.

- Find the wire from breaker points to coil.

- Cut and reroute through the TAP harness.

- Connect TAP power and ground.

- Reconnect battery and start engine in gas mode.

- Check stock timing with timing light.

- Adjust distributor rotation to increase advance for gas mode and align it with the TAP timing advance curve(e.g. LPG + ~9°, CNG + ~12°)

- Lock distributor and recheck timing.

This process uses manual distributor rotation to set how much advance the TAP will add.

Electronic Ignition with Distributor

Step-by-Step

- Locate the sensor wire (crank or cam) feeding the ignition module.

- Install TAP harness so it can intercept and modify this signal.

- Connect gas activation signal and power.

- Start engine on gas.

- Using the TAP’s trimmer or switch, adjust advance until timing light shows proper advance for gas.

- Switch back to petrol mode and confirm stock timing returns.

The key here is signal interception and correct wiring to the ignition module.

Distributorless / Crank Sensor Systems

Step-by-Step

- Identify crank sensor signal wire from engine harness.

- Wire TAP between sensor and ECU reading point.

- Tap throttle and MAP sensors if required (depending on TAP model).

- Connect gas activation signal.

- Start engine on gas and set advance curves using trimmers or software.

- Verify multiple RPM points with a timing light or scan tool.Team-BHP.com

These installations are more intricate because they deal with digital signals and ECU logic.

Software-Adjustable / Adaptive TAP Units

Step-by-Step

- Wire all required sensor inputs to the TAP as per the manual.

- Ensure correct power and ground connections.

- Connect software interface (laptop or tool).

- Load initial timing settings for LPG/CNG.

- Run engine and monitor live timing adjustments.

- Fine-tune timing maps for optimal performance in real conditions.

These setups are best done with professional tuning support so the live maps deliver safe, effective spark timing after proper ignition timing adjustment.

Summary

- Mechanical TAPs are uncomplicated and to the point and they are suitable for old systems with manual distributor adjustment and breaker points, working as a simple ignition system upgrade.

- Electronic TAPs with distributor sensor modify ignition or sensor signals and require correct wiring and trimmer setting to function properly.

- Distributorless TAPs work with crank and cam sensors and they usually deal with digital signals to trick the ECU.

- Adaptive/software TAPs are capable of reading many engine sensors and they help to tune the timing maps live for the best performance.

Selecting the proper type and correct installation will regain power and efficiency which alternative fuels can otherwise lose by ensuring reliable LPG timing advance.

Benefits of Using a Timing Advance Processor

The use of a timing advance processor presents notable benefits:

- Power and Torque Enhancement: Advancing the ignition for slower-burning fuels supports engine timing optimization and helps to keep the highest pressure timing and to regain the previously lost engine performance.

- Fuel Economy Improvement: The combustion optimization leads to more complete fuel burning, contributing to engine timing optimization, thus the consumption can be cut down.

- Operation Comfort: Right timing makes it less rough during acceleration and coasting.

- Backfire and Misfire Reduction: If the timing is right, the chance of burning problems is small.

- Emissions Decline: It is often the case that clean combustion means burning fewer hydrocarbons that could otherwise escape.

These advantages are particularly important in situations where the engine is regularly fueled with gas and requires consistent LPG timing advance and poor timing would lead to a decrease in performance.

Common Misconceptions About TAPs

There are a few myths or false beliefs that professionals should dispel:

- Timing advance processors cannot replace a full ECU tune in a modern engine but can complement simpler systems.

- Using a TAP with incorrect settings does not magically fix poor engine condition. Proper tune and maintenance still matter.

- TAPs are not universal; picking one without checking compatibility can cause misfires or drivability issues.

When installed and configured properly, a TAP will do its job without harming engine components.

How to Select the Right Timing Advance Processor

Choosing a timing advance processor requires thoughtful consideration, because the wrong timing advance controller may cause drivability problems:

- Matching the Ignition System: Find out if the engine is equipped with a mechanical distributor, an electronic ignition system with coil packs or a modern ECU control. After that, select an appropriate TAP for such system.

- Consider Fuel Type and Usage: A unit with fuel-sensitive timing curves and an emergency bypass feature would possibly be the best choice if the vehicle runs mostly on CNG or LPG, especially for those searching for the best timing advance processor for LPG.

- Look for Adjustable or Programmable Units: An adjustable processor is the one which provides a flexible and future-proof solution for fleets and performance enthusiasts. The timing curves can be changed through digital or programmable control.

- Check Build Quality and Support: The selection should be made of processors from well-known brands that have their installations adequately documented and backed up, especially when choosing any aftermarket timing device. Performance might get worse due to wrong installation.

- Seek Professional Installation: If you aren’t a mechanic, the professional installation and calibration will ensure that the timing changes are done accurately. Wrong settings in ignition timing adjustment may result in knocking, overheating, or poor fuel economy.

Troubleshooting Table for Timing Advance Processor Issues

| Symptom | Possible Cause | What to Check | How to Fix |

| Poor acceleration on CNG/LPG | Incorrect timing advance setting | Confirm TAP advance degrees | Reduce/increase advance per manufacturer guidance; retest with timing light |

| Engine backfires or rough running on gas | Too much or wrong timing | Check advance relative to base timing | Lower the advance; match to fuel combustion spee |

| Hard starting or won’t start on gas | Wiring connection error | Inspect TAP wiring and connectors | Correct loose wires; ensure solid ground and power |

| Excessive timing advance | Incorrect settings on switches/trimmer | Review DIP switch/potentiometer positions | Reset to recommended advance level |

| Check engine light / error codes | ECU detecting abnormal signals | Scan codes with OBD-II scanner | Investigate specific code; bypass TAP if needed; correct wiring or sensor issues |

| Intermittent misfire or unstable idle | Poor connection or interference | Inspect connectors, shield wires | Tighten/clean connectors; shield ignition wires; secure TAP away from heat |

| No noticeable change after installation | Wrong TAP type for ignition system | Verify system type (mechanical vs electronic) | Replace with correct TAP model for system type |

| High rpm performance drop | Fuel delivery or injector issue | Fuel system inspection | Check CNG/LPG injectors and regulator; ensure correct fuel flow |

| Knocking or pinging under load | Timing too advanced | Check actual timing with timing light | Reduce timing to eliminate detonation |

| Engine runs fine on petrol but not gas | TAP not activating or bypass engaged | Confirm gas mode activation | Make sure TAP is enabled in gas mode; check switch position |

Real-World Example

Think of a situation in which a city cab has been changed from running on petrol to CNG and benefits from a timing advance processor for CNG cars and needs correct CNG timing advance to avoid sluggish performance. The conversion without a timing advance processor causes sluggish acceleration and greater fuel consumption. The use of a TAP, however, brings back a lot of the lost torque and smoothness because it advances the ignition, thereby making combustion happen at the right moment for the fuel with longer burning time.

This kind of enhancement can have a significant impact on those drivers who need to rely on efficiency and reliability from their vehicles every day, especially when used as an ignition system upgrade.

Common Mistakes to Avoid

- Selecting a processor for the wrong type of ignition system.

- Advancing timing excessively without measurement.

- Ignoring safety features like emergency bypass.

- Installing without a proper timing light check.

These oversights often lead to disappointing results. Professional guidance at installation reduces risk.

FAQ Section

Is a timing advance processor necessary on all gas-converted cars?

Not always, but most benefit from improved combustion when stock timing is not ideal.

Can a TAP damage the engine?

Properly chosen and calibrated processors operate within safe ignition limits. Problems happen when settings are incorrect.

Does a TAP replace ECU remapping?

No. A TAP specifically adjusts timing signals externally without rewriting ECU software. ECU remapping changes many parameters in software and is considered a deeper form of ECU timing modification.

Conclusion

The timing advance processor is a small but mighty device in the performance enhancement of the engine. It acts as an interface between the factory ignition timing and the requirements of the alternative fuels such as CNG or LPG.

The processors do this by finely timing the sparks and making them coincide with the best possible moment for the engine cycle; they hence, provide the vehicle with torque, better efficiency, and running quality even in cases the ordinary timing maps do not meet the requirements. Selecting the right processor involves matching it to the ignition system, taking account of the fuel type, and ensuring proper installation and calibration.

A timing advance processor with proper TAP timing advance can increase performance without risking damage and at the same time, not cause any damage to the engine; hence it is a good upgrade for every gas engine or conversion project.